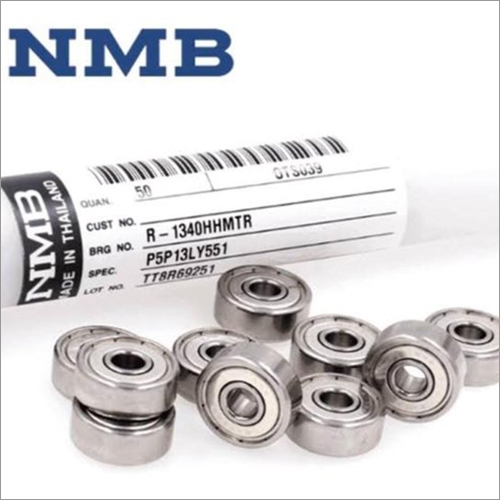

Double Raw Angular Contact Ball Bearing

350 INR/Piece

Product Details:

- Thickness 16 mm

- Weight 0.18 kg

- Material Chrome Steel

- Ball Bearing Type Angular Contact Ball Bearing

- Roller Bearing Type Double Row

- Structure Double Row Angular Contact

- Seals Type Open/Sealed

- Click to View more

X

Double Raw Angular Contact Ball Bearing Price And Quantity

- 100 Piece

- 350 INR/Piece

Double Raw Angular Contact Ball Bearing Product Specifications

- Open/Sealed

- 0.18 kg

- 20 mm

- Chrome Steel

- 20 mm

- 42 mm

- 7500 rpm

- 2400 kg

- 16 mm

- Angular Contact Ball Bearing

- Double Row Angular Contact

- Double Row

- 2

Double Raw Angular Contact Ball Bearing Trade Information

- 100 Piece Per Day

- 1 Week

- All India

Product Description

We have carved distinctive niche as a reputed manufacturer of Double Raw Angular Contact Ball Bearing. Leveraging on our advance production facility and in-depth domain knowledge, we are able to develop our products according to the demand of customers. In addition to this, our team of trained quality analysts always strives to check this Double Raw Angular Contact Ball Bearing on various parameters to ensure flawlessness.

Product Details

Brand | All Brand |

Type of Bearing | Double Raw Angular Contact Ball Bearing |

Bearing Number | 3210, 3312, 2310, 2306 |

Weight | 500gm |

Dimension | 15mm To 100mm |

Usage/Application | Industrial & Auto Sector |

Rugged Double Row Angular Contact Design

Crafted for high durability and precision, this bearings double row angular contact structure optimizes load distribution. It sustains both radial and axial forces, ensuring reliable and long-lasting performance in demanding industrial setups. The pressed steel cage enables efficient ball guidance, resulting in minimized friction and increased lifespan.

Versatility Across Industrial Applications

Designed for compatibility with pumps, gearboxes, and automotive assemblies, this bearing operates efficiently in environments where temperature fluctuates from -20C up to 120C. Its robust load rating and high limiting speed make it suitable for heavy-duty cycles and continuous operation. Available via distributor, service provider, supplier, or trader throughout India.

FAQs of Double Raw Angular Contact Ball Bearing:

Q: How should I mount the Double Row Angular Contact Ball Bearing for optimal performance?

A: Mounting should be carried out using standard procedures recommended for angular contact ball bearings, ensuring the bearing is properly aligned and not subjected to undue force. This maintains its low vibration and extends service life.Q: What lubrication type should I use for this bearing in industrial machinery?

A: You can use either grease or oil-based lubricants, depending on the operating environment and maintenance schedules. Both options are suitable, with grease commonly preferred for enclosed units and oil for high-speed applications.Q: When is it appropriate to choose the sealed version over the open version of the bearing?

A: Choose the sealed version in environments with significant dust, moisture, or contaminants, or when minimal maintenance is desired. Open bearings are suitable where regular lubrication and cleaning can be ensured.Q: Where can I find this bearing from authorized distributors or suppliers in India?

A: You can source the bearing through recognized distributors, service providers, suppliers, or traders specializing in industrial equipment and automotive components across India. Verify distributor credentials for authenticity.Q: What is the process for ensuring proper lubrication and maximizing bearing longevity?

A: Establish a routine lubrication schedule tailored to your machinerys operational requirements. Monitor lubricant quality and replace or replenish as needed to prevent wear, reduce friction, and maintain high performance.Q: How can using the Double Row Angular Contact Ball Bearing benefit my equipment?

A: This bearing offers enhanced load capacity, low vibration, and stable operation at high speeds. Its P5 precision rating and robust materials result in fewer breakdowns, reduced maintenance costs, and consistent productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS