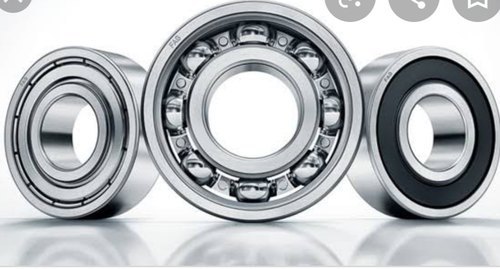

Axial Angular Contact Ball Bearing

5000 INR/Piece

Product Details:

- Weight Approx. 0.7 kg

- Thickness 23 mm

- Material Chrome Steel

- Ball Bearing Type Axial Angular Contact Ball Bearing

- Structure Angular Contact

- Seals Type Open/Sealed Options

- Number Of Rows Double Row

- Click to View more

X

Axial Angular Contact Ball Bearing Price And Quantity

- 1000 Piece

- 5000 INR/Piece

- 16500 N

- 12000 N

- -30°C to +120°C

- Grease

- Steel

- P6

- Machine Tools, Pumps, Gearboxes

- 40 Degrees

Axial Angular Contact Ball Bearing Product Specifications

- 8000 rpm

- Open/Sealed Options

- Chrome Steel

- Heavy Duty

- 80 mm

- 40 mm

- Approx. 0.7 kg

- Double Row

- Axial Angular Contact Ball Bearing

- Angular Contact

- 40 mm

- 23 mm

- 16500 N

- 12000 N

- -30°C to +120°C

- Grease

- Steel

- P6

- Machine Tools, Pumps, Gearboxes

- 40 Degrees

Axial Angular Contact Ball Bearing Trade Information

- 1000 Piece Per Week

- 1 Week

Product Description

Axial Angular Contact Ball Bearing

Product Details

Origin | Europe |

Bearing Number | BTW 80 |

Weight | 2 kg |

Dimension | 25 mm |

Usage/Application | CNC Machine |

Shape | Round |

Part Number | Precision |

Packaging Type | Box |

Material | Mild Steel |

Brand | NSK / SKF / FAG |

Engineered for Demanding Applications

Designed to excel in machine tools, pumps, and gearboxes, this double row axial angular contact ball bearing offers robust support for heavy-duty requirements. The 40-degree contact angle efficiently handles both axial and radial loads, while the chrome steel construction ensures lasting durability and resistance to high temperatures.

Precision and Performance Combined

Rated at P6 precision, this bearing delivers reliable accuracy and smooth operation. Its ability to handle high speeds (up to 8,000 rpm) and significant dynamic and static loads makes it a top choice for industries needing dependable performance under challenging conditions.

Flexible Lubrication and Sealing Options

With grease lubrication and the availability of both open and sealed types, the bearing suits diverse environments and application demands. These features provide enhanced protection against contaminants and allow for lower maintenance in harsh working conditions.

FAQs of Axial Angular Contact Ball Bearing:

Q: How do I install the double row axial angular contact ball bearing correctly?

A: For optimal performance, install the bearing by aligning it precisely on the shaft and housing, ensuring that cleanliness is maintained to prevent contamination. Properly apply the recommended grease and use appropriate tools to avoid damaging the bearing during installation.Q: What are the benefits of the 40-degree contact angle in this bearing?

A: The 40-degree contact angle allows the bearing to manage substantial axial and radial loads simultaneously, making it particularly effective in applications where high thrust and durability are required, such as gearboxes and machine tools.Q: Where can these bearings be applied in industrial settings?

A: These axial angular contact ball bearings are commonly used in machine tools, pumps, and industrial gearboxes. Their high load capacity and precision make them ideal for critical rotating assemblies requiring stability and strength.Q: What process should be followed for maintaining the bearings performance?

A: Regularly inspect the bearing for signs of wear or contamination, ensure the grease lubrication is replenished as needed, and select appropriate sealing options based on the operating environment to prolong service life.Q: When should I choose an open type versus a sealed type bearing?

A: Select the open type for applications where regular maintenance and re-lubrication are feasible; use the sealed type in environments prone to dust or moisture to protect against contaminants and reduce maintenance frequency.Q: What advantages does chrome steel material offer in these bearings?

A: Chrome steel provides exceptional hardness, corrosion resistance, and fatigue endurance, contributing to the bearings ability to operate reliably under heavy loads and in a wide temperature range from -30C to +120C.Q: How does the P6 precision rating benefit my machinery?

A: The P6 precision rating ensures tight tolerances and reduced vibration, resulting in smoother operation, higher accuracy, and longer lifespan for machinery components utilizing these bearings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS