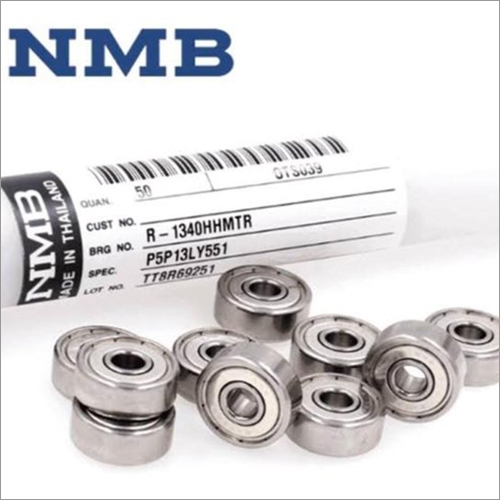

SS Ball Bearing

Product Details:

- Weight 0.032 kg

- Thickness 11 mm

- Material Stainless Steel (SS)

- Ball Bearing Type Deep Groove Ball Bearing

- Structure Single Row

- Seals Type Metal Shielded/Sealed

- Number Of Rows 1

- Click to View more

SS Ball Bearing Price And Quantity

- 10 Piece

- 90.0 INR/Piece

- ISO 9001:2015

- High

- Automobile, Machinery, Electric Motors

- Box

- ABEC 3

- Pre-lubricated with Grease

- -20°C to +180°C

- Polished

SS Ball Bearing Product Specifications

- Deep Groove Ball Bearing

- 12000 RPM

- 15 mm

- Metal Shielded/Sealed

- 2300 N

- 15 mm

- 35 mm

- Stainless Steel (SS)

- 1

- Single Row

- 11 mm

- 0.032 kg

- ISO 9001:2015

- High

- Automobile, Machinery, Electric Motors

- Box

- ABEC 3

- Pre-lubricated with Grease

- -20°C to +180°C

- Polished

SS Ball Bearing Trade Information

- 100 Piece Per Week

- 1 Week

- All India

Product Description

With an aim to fulfil variant requirements of our prestigious clients, we bring forth a comprehensive assortment of SS Bearing. This steel bearing is offered to the customer in complete safe body that remains sustained in rough conditions such as pressure, temperature and rough weather. In addition to this, our qualitative SS Bearing is vastly acknowledged by our esteemed clients from every nook and corner of the nation. Sturdy construction, dimensionally accurate and anti-abrasive is features of offered bearing.

Product Details

|

Structure |

Ball Bearing |

|

Type of Bearing |

Stainless Steel Ball Bearing |

|

Bearing Number |

S 608 Zz, S 6000 Zz, S 6202 -2rs, S 6303 Zz |

|

Weight |

100gm |

|

Size |

5mm Onwards |

|

Dimension |

5mm To 100 Mm |

|

Usage/Application |

Water Base & Chemical Base Industries |

|

Part Number |

Ss |

|

Number Of Rows |

Single Row |

|

Material |

Stainless Steel |

|

Brand |

Ezo , Kyl |

Superior Performance & Durability

Designed for demanding environments, the ABEC 3 precision-rated stainless steel bearing delivers high reliability and smooth rotation. Its corrosion resistance and polished finish make it especially suitable for applications in automobiles, machinery, and electric motors, even under variable temperature conditions. The pre-lubricated, metal-shielded design enhances operational longevity, ensuring lasting performance and reduced maintenance.

Comprehensive Quality Assurance

Manufactured to ISO 9001:2015 standards, this deep groove ball bearing undergoes stringent testing for both structure and finish. As a certified distributor, service provider, supplier, and trader in India, we ensure each product meets industry benchmarks for quality and safety. Secure packaging in boxes guarantees the bearing arrives intact and ready for immediate installation.

FAQs of SS Ball Bearing:

Q: How do I install the SS Deep Groove Ball Bearing in machinery or electric motors?

A: Install the bearing by aligning the inner diameter (15 mm) with the shaft and gently pressing it into place. Ensure the metal shields or seals face outward for optimal protection. Follow manufacturers guidelines for fitment to guarantee smooth operation.Q: What benefits does the ABEC 3 precision rating provide for automotive and machinery applications?

A: The ABEC 3 rating ensures higher precision, reduced vibration, and smoother rotation, making it ideal for critical machinery and automotive uses where reliability and accuracy are essential.Q: When should I consider replacing these stainless steel ball bearings?

A: Replace the bearing if you notice increased noise, reduced speed, signs of wear, or if performance falls below expected levels despite maintenance. Regular inspection helps identify issues early, especially in high-speed or heavy-load environments.Q: Where can these bearings be used given their high corrosion resistance?

A: These polished stainless steel bearings are suitable for use in corrosive or humid environments, including automotive components, machinery subjected to moisture, and electric motors operating under varying conditions.Q: What is the process used to ensure the bearings are pre-lubricated and protected during transport?

A: Before packaging, each bearing is pre-lubricated with grease and securely sealed with metal shields. They are then packed in sturdy boxes to safeguard against contamination and physical damage during distribution.Q: How does the pre-lubrication with grease affect the bearings operation and maintenance needs?

A: Pre-lubrication with grease minimizes initial maintenance, improves operational smoothness, and protects against contamination, ensuring the bearing remains reliable over time with reduced need for frequent relubrication.Q: What advantages does buying from an ISO 9001:2015 certified supplier in India offer?

A: Purchasing from an ISO 9001:2015 certified distributor in India assures you of consistent quality, structured processes, and dependable service, backed by strict adherence to international standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS