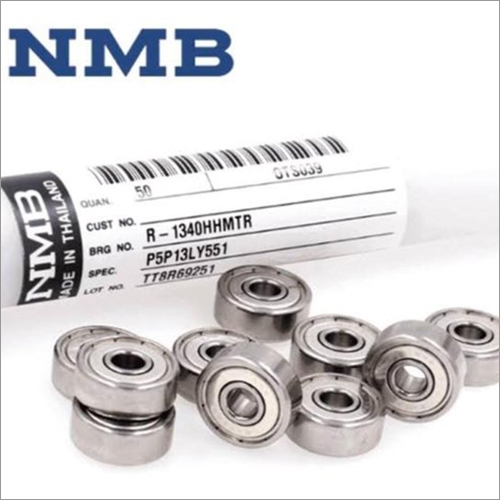

Ceramic Ball Bearing

Product Details:

- Thickness 7 mm

- Weight 14 g

- Material Ceramic

- Ball Bearing Type Deep Groove

- Structure Single Row

- Seals Type Open / Sealed

- Number Of Rows 1

- Click to View more

Ceramic Ball Bearing Price And Quantity

- 1000 Piece

- 500 INR/Piece

- Polyamide / Stainless Steel

- High

- Low

- -40°C to 200°C

- Yes

- P6

- Polished

- Electric Motors, High-Speed Equipment, Medical Devices

Ceramic Ball Bearing Product Specifications

- 22 mm

- 14 g

- Open / Sealed

- Ceramic

- 1

- Single Row

- 1760 N

- 7 mm

- Deep Groove

- 8 mm

- 8 mm

- 32000 RPM

- Polyamide / Stainless Steel

- High

- Low

- -40°C to 200°C

- Yes

- P6

- Polished

- Electric Motors, High-Speed Equipment, Medical Devices

Ceramic Ball Bearing Trade Information

- 1000 Piece Per Week

- 1 Week

- All India

Product Description

With the inclusion of advanced technology and innovative machines, we are engaged in offering a comprehensive range of Ceramic Ball Bearing. This ball bearing is widely used in mechanical and automobile industry. The range offered by us is manufactured using premium quality raw material and advanced techniques in strictly adhering to set industrial standards. Also, we offer this Ceramic Ball Bearing in different customized options in order to satisfy variegated demands of our clients spanning all across the country.

Product Details

| Structure | Full Ceramic , Only Ball Ceramic |

| Type of Bearing | Ceramic Ball Bearing |

| Bearing Number | Deep Groove Ball Bearing |

| Weight | 250gm Onwards |

| Size | 8mm Onwards |

| Dimension | 8 MM Onwards |

| Usage/Application | HIgh Speed , High Temparature |

| Number Of Rows | Single Row |

| Material | Stainless Steel & Ceramic |

| Brand | Special Brands |

Optimal Performance for Critical Applications

This ceramic ball bearing is tailored for demanding environments, including electric motors, medical devices, and high-speed machinery. Its single-row, deep groove structure offers outstanding speed capability and load handling, while low operational noise ensures suitability for sensitive equipment. With options for open or sealed designs, you maintain flexibility in various installation requirements.

Unmatched Durability and Corrosion Resistance

Fabricated entirely from ceramic materials and available with either polyamide or stainless steel cages, the bearing exhibits excellent corrosion resistance and longevity, even in harsh or moisture-prone settings. Operating reliably across a wide temperature range, the polished finish further adds to the efficiency and durability, reducing maintenance needs.

FAQs of Ceramic Ball Bearing:

Q: How does the ceramic construction benefit the ball bearings performance in electric motors and medical devices?

A: Ceramic materials offer superior hardness, low friction, and excellent corrosion resistance. This enhances durability, promotes smoother motion, and ensures low noise, making the bearing ideal for electric motors and sensitive medical equipment.Q: What are the operating temperature ranges for this ceramic ball bearing?

A: This bearing is designed for a broad operating temperature range, functioning efficiently from -40C up to 200C, suiting both low and high-temperature industrial environments.Q: Where can this ceramic ball bearing be utilized most effectively?

A: It is best suited for high-speed equipment, electric motors, and medical devices requiring low vibration, low noise, and high precision, especially where exposure to corrosive elements may be a concern.Q: What is the process for selecting the right seal type for my application?

A: Choosing between open or sealed types depends on your applications exposure to contaminants. Sealed bearings offer better protection in dusty or moist environments, while open types are appropriate for cleaner, controlled settings where easy lubrication is desired.Q: When should a polyamide cage be chosen over a stainless steel one in this bearing?

A: A polyamide cage provides lightweight, low-noise operation and is suitable for moderate temperatures, while a stainless steel cage is recommended for higher temperatures, more demanding loads, or chemically aggressive environments.Q: How does this bearing handle high-speed requirements?

A: With a limiting speed of 32,000 RPM and high vibration resistance, this deep groove, single-row bearing is engineered to support demanding high-speed applications without compromising on performance or lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS