Ball Screw Support Bearing

Product Details:

- Cage Material Steel / Brass

- Thickness 15 mm

- Inside Diameter 20 mm

- Retainer Metal

- Precision Rating P4 / P5

- Lubrication Type Grease / Oil

- Bearing Type Ball Screw Support Bearing

- Click to View more

Ball Screw Support Bearing Price And Quantity

- 1000 Piece

- 950 INR/Piece

Ball Screw Support Bearing Product Specifications

- Chrome steel

- 20 mm

- 15 mm

- High Load

- 20 mm

- Single Row

- Steel / Brass

- Ball Screw Support Bearing

- Angular Contact

- Grease / Oil

- 12,000 rpm

- Open / Sealed

- P4 / P5

- 47 mm

- Metal

Ball Screw Support Bearing Trade Information

- 1000 Piece Per Week

- 1 Week

Product Description

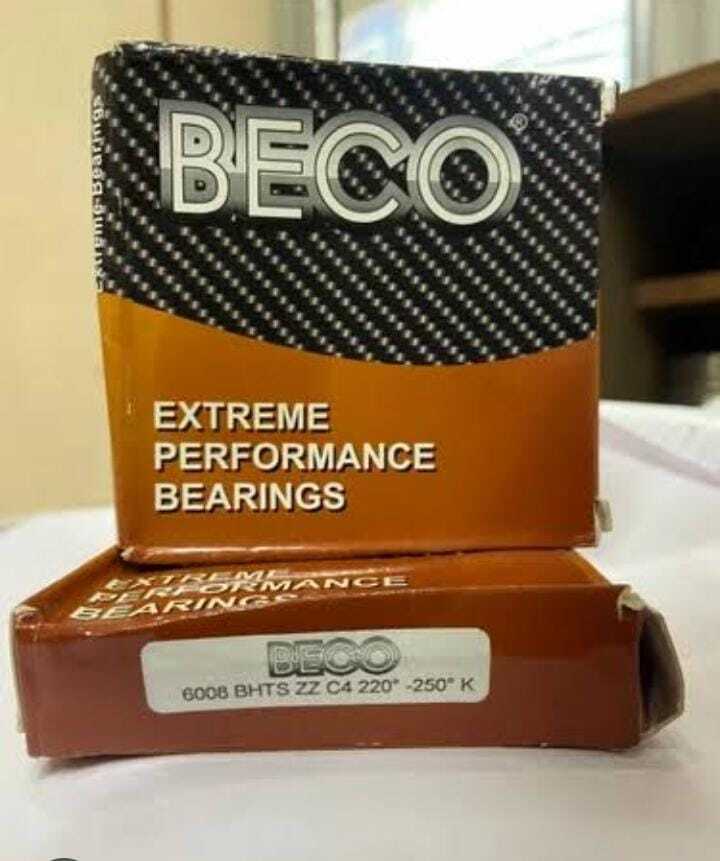

Ball Screw Support Bearing

Ball Screw Support Bearing is a circular machine element that is designed to minimize friction and noise within high-speed industrial machines. It is provided with two concentric rings in between which steel balls are placed to ensure smooth rotation of shafts and other rotating elements within transmission systems. The offered Ball Screw Support Bearing also gives excellent resistance against rust and corrosion due to the silver-colored anti-corrosive coating that adds extra life to the bearing.

Product Details

Structure | Ball |

Type of Bearing | Ball |

Bearing Number | 25 Tac 62, 30 Tab 06, Bsb 025062, Mm30bs62, Bsb 100 |

Weight | 250gm |

Size | 15mm Onwards |

Dimension | 15mm Onwards |

Usage/Application | Spindle & Cnc Machine |

Part Number | 20tac, Bsb 3062 |

Number Of Rows | Single Row |

Brand | Nsk/Rhp, Ffafnir, Skf |

High Precision for Demanding Applications

This bearing meets JIS/ISO standards and boasts a 60 contact angle, making it especially suitable for CNC machines and precise motion systems. With high tolerance ratings (P4/P5), it enables consistent accuracy under heavy loads and rapid speeds, supporting the requirements of advanced manufacturing processes.

Durable Design and Versatile Performance

Constructed from polished chrome steel, the bearing features a single-row angular contact structure and is available in open or sealed configurations. Its robust design, metal retainer, and choice of cage material (steel/brass) provide durability and flexible lubrication options, ensuring optimal performance in various operating conditions.

Quiet, Reliable Operation Across Temperatures

Engineered for low noise, this bearing is suitable for use in environments ranging from -20C to +120C. Its sealed or open options, along with grease or oil lubrication, allow for customized setups that deliver stable, reliable operation with minimal maintenance needs.

FAQs of Ball Screw Support Bearing:

Q: How is the Ball Screw Support Bearing mounted in CNC machines and precision equipment?

A: This bearing employs a direct mounting type, which simplifies installation in CNC machines or precision systems. Its dimensional consistency and high-precision tolerance ensure accurate and secure fitting into the designated housing, supporting smooth and reliable motion transfer.Q: What are the advantages of the 60 contact angle in this bearing?

A: A 60 contact angle enhances the bearings ability to support substantial axial loads, which is crucial in ball screw applications where both precision and stability are required. This feature enables the bearing to maintain alignment and reduce deformation during high-speed or heavy-load operation.Q: When should I use the open versus the sealed bearing configuration?

A: Use the sealed variant in environments prone to contamination, as it offers better protection against dust and moisture, helping extend bearing life. The open type, on the other hand, is preferable when regular maintenance and re-lubrication are possible, or when lower friction is desirable under clean operating conditions.Q: Where are these ball screw support bearings typically applied?

A: These bearings are primarily utilized in CNC machines, precision positioning stages, robotics, and other industrial machinery requiring accurate linear motion and high load support. Their versatility makes them suitable for a broad range of advanced manufacturing and automation systems.Q: What is the process for ensuring optimal lubrication and longevity of the bearing?

A: Regular lubrication with appropriate grease or oil is recommended, according to the operating environment and load conditions. Its important to follow manufacturer guidelines for re-lubrication intervals, especially for open bearings, to ensure smooth performance and maximize service life.Q: How does the bearings high dynamic (C) and static (Co) load ratings benefit my application?

A: With dynamic and static load ratings of 12,200 N and 24,100 N, respectively, this bearing can endure high operational loads and occasional heavy impacts without compromising performance. Such capacity ensures durability and reliability in demanding industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS